$343.00 Original price was: $343.00.$99.99Current price is: $99.99.

- Free Shipping Worldwide

- Safe Transactions, Always

- Buy with confidence, backed by quality.

- Online customer care, always here for you.

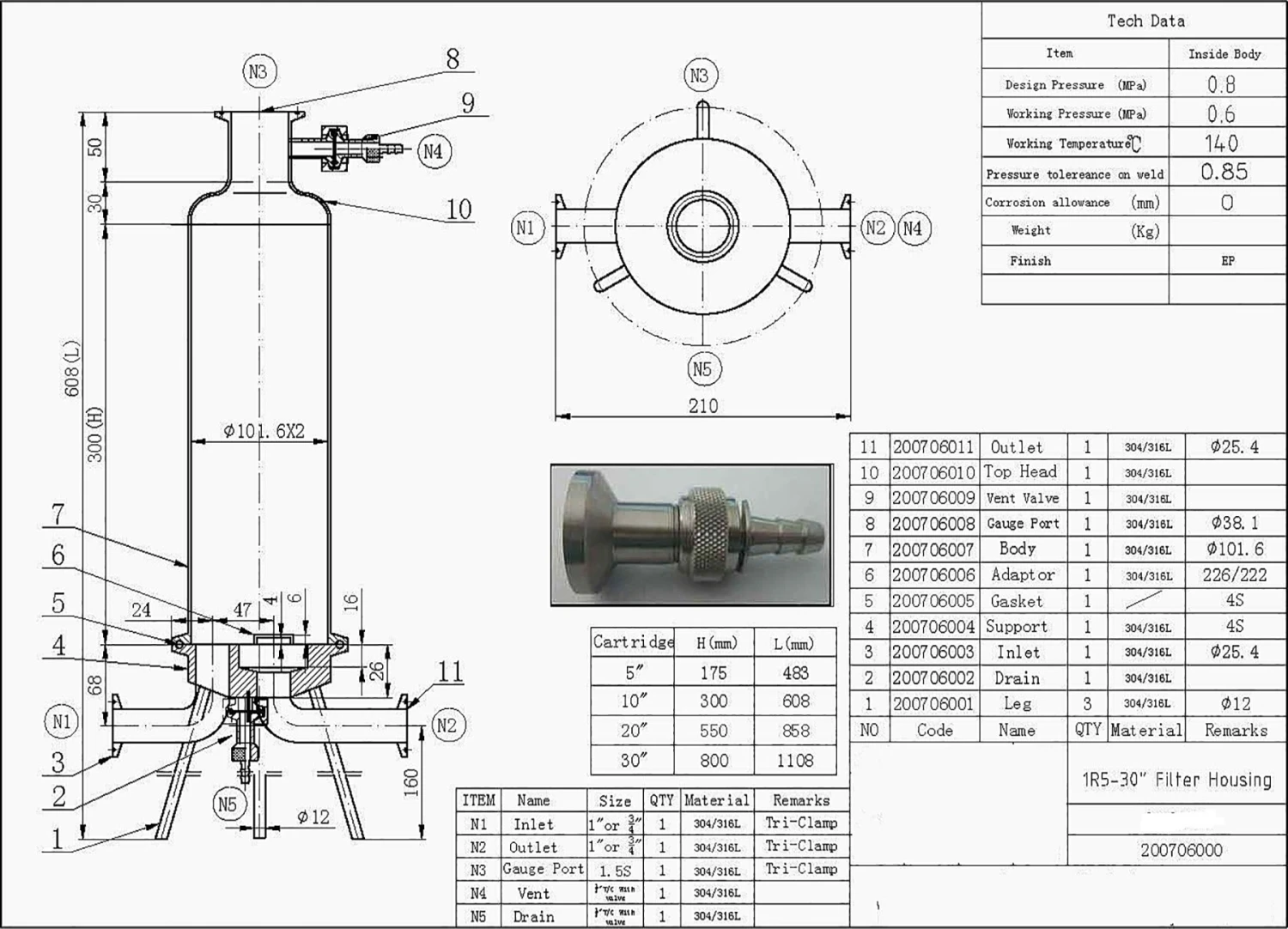

Ideal for sterile filtration applications, the vessel design offers positive seal preventing fluid bypass. The machine seat plate provides lower pressure drops in air and gas applications. The type 316 low carbon stainless steel construction offers longevity and superior corrosion resistance. The tri-clamp does not require the use of any special tools for opening and closing. Rated for 90 PSI with 1″ or 1.5″ sanitary pipe fitting options available, the tri-clamp design allows for quick release and easy cartridge installation, while the 1/2″ drain and vent ports offer complete evacuation prior to change out and bleeding off of air during start-up.

This filter vessel can accept cartridges 10″ in length up to 2.7″ OD in DOE, 222/Fin or 226/Fin configurations. Configurable options on our type 316L stainless steel sanitary filter housings include inlet/outlet size, end configuration and gasket/O-ring for optimum chemical compatibility. Customize the 0.5″ vent and drain with tri-clamp and welded sanitary options available.

Key benefits

- Aseptic design

- Mechanic polish with additional electropolish. Interior: Ra 20 µin; Exterior: 32 µin;

- Maximum operating pressure of 90 psi (6 bar)

- Type 316 SS head, bowl, vent/drain plug

- Type 304 SS clamp

- Low point drain valve removable for cleanability

- Low hold volume

- Configurable inlet/out & vent/drain

Applications: Pharmaceuticals, Biologics, Fine Chemicals, Electronics, High Purity Water, Process Water, Beverages, Tank Vents, etc.

Material:

Disclaimer:

This information has been provided as a general guide. It is the customer’s responsibility to select the proper container for product and application compatibility.

Additional Information

| Material | Stainless Steel (316L) |

|---|---|

| Bag/Cartridge Qty | Single |

| Housing Size | 10″ |

| Pipe Size | Configurable |

| Outlet Style | Configurable |

| Pressure Rating | 90 PSI |

| Basket Style | Cartridge |

| Pallet Pack | 20 ea. |

| Weight | 20 lbs. |

| Note: | Expert Help – Need help with a unique specification or more information on pricing? Speak to one of our Liquid Filtration Experts to find the best solution for your application! — Call 630.629.6600 or email today! |

Be the first to review “10″ Type 316L SS Single Cartridge Sanitary Housing With “T” Style Tri-Clamp Pipe Fittings (Configurable)” Cancel reply

Related products

Industrial Filtration

Industrial Filtration

25 Micron Polypropylene Melt Blown Liquid Filter Cartridge (2-1/2″ X 30″)

Industrial Filtration

20″ X 25″ X 12″ Rigid Cell Air Filter, Single Header, MERV 13

Industrial Filtration

Industrial Filtration

3/8″ Mesh Testing Sieve, 8″ Dia., 2″ Depth (Full), SS Frame, SS Wire Cloth

Industrial Filtration

20″ X 24″ X 2-1/8″ Galvanized Steel Air Filter Holding Frame W/Gasket And Clips

Industrial Filtration

Industrial Filtration

String Wound Filter Cartridges – 4-1/2″ X 20″ – 316 SS Core (Customizable)

Reviews

There are no reviews yet.