$13.05 Original price was: $13.05.$9.14Current price is: $9.14.

SKU: DGHLY 79738191 Category: Industrial Filtration

- Free Shipping Worldwide

- Safe Transactions, Always

- Buy with confidence, backed by quality.

- Online customer care, always here for you.

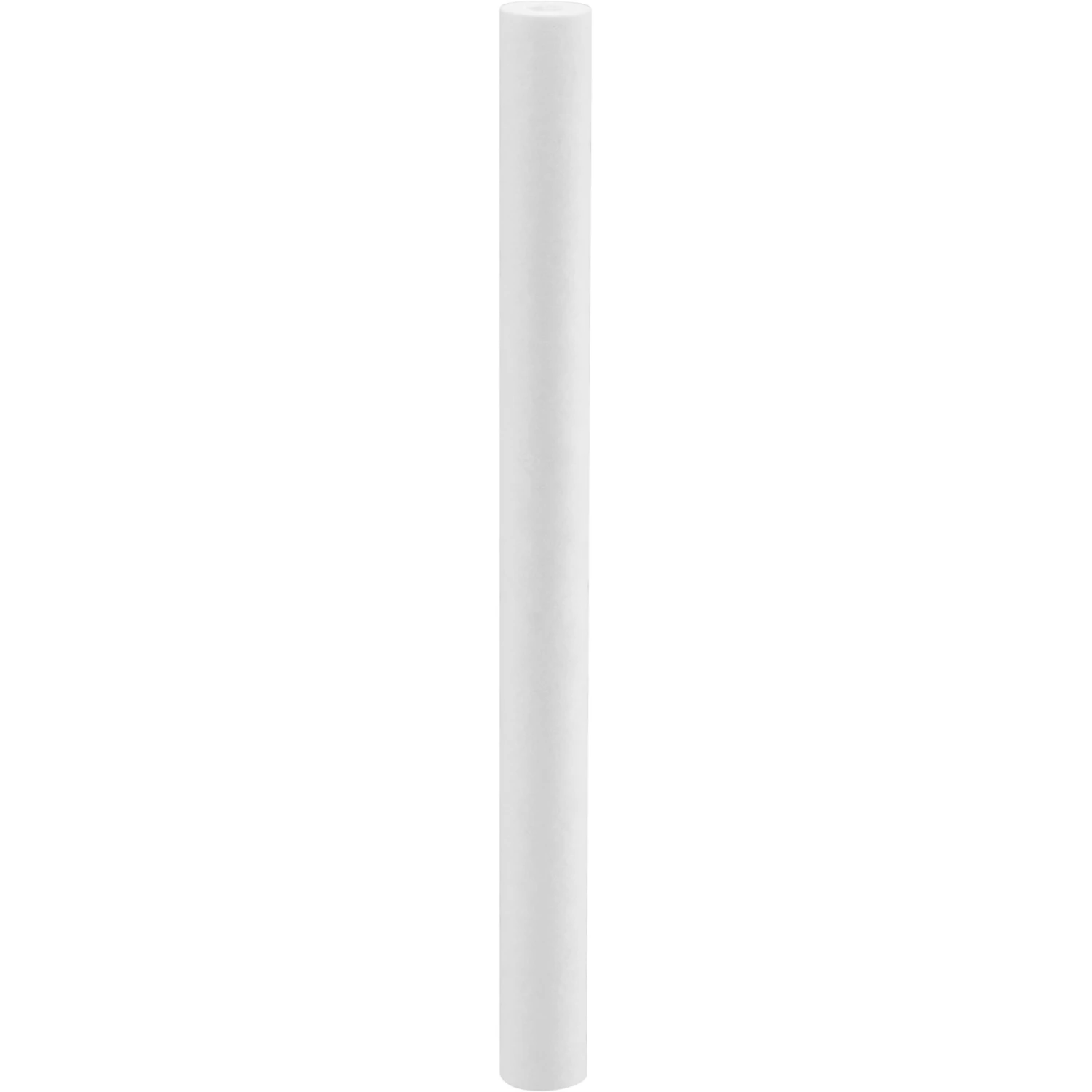

The 25 Micron 30″ Length Melt Blown Polypropylene Filter Cartridge has high dirt holding capacity. Liquid filter cartridges are commonly used in the electronics, cosmetic, aerosil products, and water based paints industry.

Key benefits:

- Maximum operating temperature is 155°F

- Maximum differential pressure is 35 psid with a core

- Tested and certified to NSF/ANSI 61 Standard & NSF/ANSI 42 Standard for Component

- All elements are made with FDA compliant material for food and beverage contact under CFR Title 21

Downloads:

Specification Sheet

Material:

Polypropylene (PP) is a tough plastic that has excellent chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color. Some examples of common products made with PP are dairy and medication containers. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclaving. It is not recommended for cold or sub-freezing temperatures. The Cary Company has an assortment of polypropylene plastics available for purchase, such as plastic caps and jars, which have a higher tolerance for chemical products. Discover if Polypropylene is appropriate for hot fill application by learning more about What Is Hot Fill Packaging and how it applies to Polypropylene containers.

Polypropylene (PP) is a tough plastic that has excellent chemical resistance. PP is translucent in its natural state but can have a glossy finish when produced with color. Some examples of common products made with PP are dairy and medication containers. Polypropylene is suitable for hot fill applications of up to 165°F and is therefore great for autoclaving. It is not recommended for cold or sub-freezing temperatures. The Cary Company has an assortment of polypropylene plastics available for purchase, such as plastic caps and jars, which have a higher tolerance for chemical products. Discover if Polypropylene is appropriate for hot fill application by learning more about What Is Hot Fill Packaging and how it applies to Polypropylene containers.Disclaimer:

This information has been provided as a general guide. It is the customer’s responsibility to select the proper container for product and application compatibility.

Additional Information

| Material | PP |

|---|---|

| Size | 30″ (76.2 cm) |

| Micron Rating | 25 Micron |

| Case Pack | 25 ea. |

| Pallet Pack | 525 ea. (21 Cases) |

| Country of Manufacture | United States |

| Note: | *Does not come with end caps. |

Be the first to review “25 Micron Polypropylene Melt Blown Liquid Filter Cartridge (2-1/2″ X 30″)” Cancel reply

Related products

Sale!

Industrial Filtration

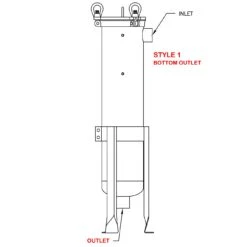

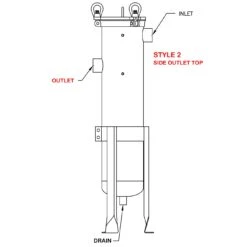

#1 Size Stainless Steel 1/16″ Perforated Restrainer Basket For Vessel

Sale!

Industrial Filtration

Sale!

Industrial Filtration

Sale!

Industrial Filtration

Sale!

Industrial Filtration

20″ X 24″ X 2-1/8″ Galvanized Steel Air Filter Holding Frame W/Gasket And Clips

Sale!

Industrial Filtration

Sale!

Industrial Filtration

6-3/4″ X 42″ PE Sateen Baghouse Dust Filter, Loop Top Snap Band Bottom

Sale!

Industrial Filtration

Reviews

There are no reviews yet.